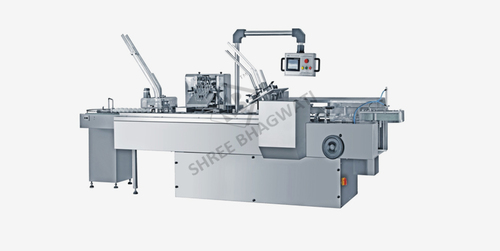

AUTOMATIC SHRINK WRAPPING MACHINE

Price 1500000 INR/ Unit

AUTOMATIC SHRINK WRAPPING MACHINE Specification

- Type

- Wrapping Machines

- Material

- Stainless steel

- Auxiliary Packaging Machine Type

- Other

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Drive Type

- Electric

- Power

- As per the client required Watt (w)

- Voltage

- As per the client required Watt (w)

- Warranty

- 1 year

AUTOMATIC SHRINK WRAPPING MACHINE Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- India

- Payment Terms

- Cash Against Delivery (CAD), Days after Acceptance (DA), Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 30 Units Per Week

- Delivery Time

- 4-6 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden packing only

- Main Domestic Market

- All India

- Certifications

- ISO and CE certified

About AUTOMATIC SHRINK WRAPPING MACHINE

Technical Specifications

| Packaging speed | Up to 10 PCS /Minute |

| Transfer belt width | 550mm |

| Sealing and cutting time/temperature | 0.5-1.5s 180C-260C |

| Operating power supply/power | 380V 30kw |

| Operating air pressure | 0.6-0.8Mpa |

| Air Consumption | 0.6m3/minute |

Precise PLC-Controlled Automation

Equipped with an advanced PLC control system, this shrink wrapping machine guarantees accurate and consistent operation. The automated grade minimizes manual intervention, resulting in improved productivity and reduced human error.

Customizable Power and Voltage Options

The machine offers flexible power and voltage configurations tailored to specific client requirements, ensuring seamless integration into various production environments. This adaptability enhances compatibility and efficiency for manufacturers.

FAQs of AUTOMATIC SHRINK WRAPPING MACHINE:

Q: How does the Automatic Shrink Wrapping Machine operate?

A: The machine uses electric drive and PLC control to automate the process of wrapping products in shrink film. Operators can set preferences on the computerized interface, and the system manages temperature, film feed, and sealing, resulting in consistent shrink wrapping outcomes.Q: What materials can be processed using this wrapping machine?

A: This machine is suitable for a wide range of products, primarily using shrink film. Its stainless steel construction enables robustness and easy cleaning, making it ideal for packaging items in electronics, food, pharma, and consumer goods industries.Q: When is shrink wrapping recommended for packaging?

A: Shrink wrapping is recommended when protection, tamper evidence, and aesthetic enhancement are essential. Manufacturers or suppliers typically use automated shrink wrapping for bulk orders and high-volume production to ensure fast, uniform packaging.Q: Where can clients purchase or source this shrink wrapping machine in India?

A: The machine is available through various authorized distributors, exporters, manufacturers, and suppliers across India. Interested parties can contact these vendors directly to customize orders according to specific power and voltage needs.Q: What is the process for setting up and using the machine?

A: Upon installation, operators must input client-specific voltage or power settings. The packaging process is then managed through computerized controls, where users choose wrapping parameters, activate the machine, and monitor operations via the PLC system.Q: How does the automatic grade benefit users compared to manual wrapping methods?

A: The automatic function greatly reduces the need for manual labor, minimizes errors, and accelerates the wrapping speed. This boost in productivity translates to lower operational costs and more consistent, high-grade packaging outcomes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Automatic Packaging Machine Category

Cartooning Machine Bottle

Minimum Order Quantity : 1 Piece

Computerized : No

Material : SS

Voltage : 220415 Volt (v)

Automatic Grade : SemiAutomatic

Automatic 2 head Volumetric Filling Machine

Price 3500000 INR / Number

Minimum Order Quantity : 1 Number

Computerized : Yes

Material : Stainless Steel (SS 304/316)

Voltage : 220V / 380V, 50/60 Hz Volt (v)

Automatic Grade : Automatic

Automatic 4 Head Servo PLC Base Viscous Juice Filling Machine

Price 1200000 INR / Number

Minimum Order Quantity : 1 Number

Computerized : Yes

Material : Stainless Steel

Voltage : 220V/380V (customized as per requirement) Volt (v)

Automatic Grade : Automatic

Servo Auger Type VFFS Spices Powder Pouch Packing Machine

Price 1600000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Material : Stainless steel

Voltage : As per the client required Watt (w)

Automatic Grade : Automatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free