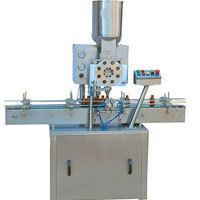

Auger Powder Filling Machine

Price 600000.00 INR/ Unit

Auger Powder Filling Machine Specification

- Features

- Good Quality

- Usage

- Industrial

- Power Supply

- Electric

- Material

- SS

- Computerized

- No

- Automatic Grade

- Automatic

- Drive Type

- Electric

- Color

- Silver

- Warranty

- 1 Year

Auger Powder Filling Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 30 Pieces Per Month

- Delivery Time

- 4-6 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Packing Only

- Main Domestic Market

- All India

- Certifications

- CE & ISO Certified

About Auger Powder Filling Machine

Auger Powder Filling - Powder Filler Machine

Bhagwati makes Powder Filling Machines, Powder Fillers, Auger Filling Machine, Volumetric Fillers, Auger Filling Line, & Powder Filling Equipment Powder filling machine is majorly used for filling free-flowing powders and non-free-flowing powders. Powder filling machine is also known as auger filler and powder dozing machine which is suitable to fill 1gm to 5000gm

A.C. Frequency drives for Conveyor drive.

Technical Specifications:

| Product | Powder |

| Direction | Left To Right. |

| Output | Up to 7,000 to 10,000 Bottles per day Depend on fill size |

| Fill Capacity | 20gm to 1kg with help of change parts |

| Powder Accuracy | 1% |

| No. Of Heads | Single |

| Electrical Supply | 2.00 HP For Main Drive. 0.25 HP for conveyor |

| Power Requirement | 440 Volts, 3 Phase (4 wire System) 50 Hz. |

| Height of Conveyor | Adjustable from 800 To 850 MM |

| Pneumatic Air | Filtered, oil-free, sterile low-pressure AIR at 5kg/cm2 |

Exceptional Productivity and Reliability

Built with stainless steel, the Auger Powder Filling Machine delivers both durability and high performance. Suitable for filling between 7,000 and 10,000 bottles per day, it integrates seamlessly into fast-paced industrial environments, reducing downtime and boosting throughput with precise, automated operation.

Advanced Control and Customization

This machine is equipped with a modern PLC control system, offering reliable computerized command over filling operations. Electric drive and customer-specific voltage customization ensure the system matches unique site requirements, while the automatic grade guarantees operational efficiency and reduced manual intervention.

FAQs of Auger Powder Filling Machine:

Q: How does the Auger Powder Filling Machine operate in industrial environments?

A: The machine uses an electric auger mechanism and PLC control system to automatically fill bottles with powder at high speed. Stainless steel construction ensures it can handle daily industrial use efficiently and hygienically.Q: What is the filling capacity of the machine per day?

A: The Auger Powder Filling Machine is capable of filling between 7,000 and 10,000 bottles per day, making it suitable for large-scale production lines and high-volume distribution needs.Q: When can customers expect technical support or service?

A: Customers receive a 1-year warranty with every machine. This includes technical support and service assistance for any operational or manufacturing defects during the warranty period, ensuring the operation remains smooth and uninterrupted.Q: Where is this machine manufactured and supplied from?

A: This filling machine is manufactured and distributed from India, and is available for clients nationwide including exporters, distributors, and suppliers seeking high-quality powder filling solutions.Q: What process does the Auger Powder Filling Machine follow for accurate filling?

A: The process is fully automatic and controlled through a PLC system that adjusts the auger to dispense precise powder volumes into each bottle, guaranteeing consistent fills and minimal product wastage.Q: How is the machine powered and what voltage options are available?

A: Powered by electricity, the machines voltage can be configured according to the specific requirements of the customer, ensuring compatibility with various industrial setups.Q: What are the primary benefits of using this stainless steel automatic filling machine?

A: Key benefits include high-speed operation, excellent build quality, reduced manpower needs due to automation, computerized accuracy, easy cleaning, and robust steel construction that supports industrial-scale output and longevity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Powder Filling Machine Category

Automatic Two Head Powder Filling Machine

Price 1100000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless steel

Computerized : Yes

Automatic Grade : Automatic

Warranty : 1 year

Double Head Auger Type Powder Filling Machine

Price 1200000 INR / Unit

Minimum Order Quantity : 1 Piece

Material : SS

Computerized : No

Automatic Grade : Automatic

Warranty : 1 Year

Dry Syrup Powder Filling Machine

Minimum Order Quantity : 1 Piece

Material : SS

Computerized : No

Automatic Grade : Automatic

Warranty : 1 Year

High Speed Dry Syrup Powder Filling Machine

Price 1200000 INR / Number

Minimum Order Quantity : 1 Piece

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free