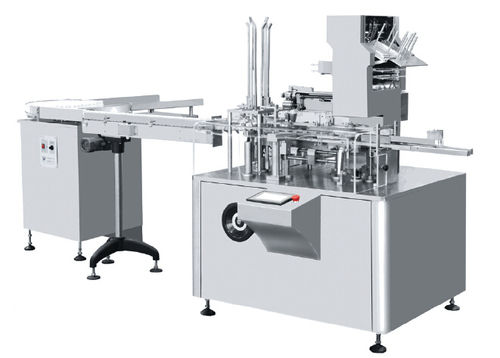

Vial Filling and Cap Sealing Machine

Vial Filling and Cap Sealing Machine Specification

- Power Supply

- Electric

- Features

- Good Quality

- Usage

- Industrial

- Material

- SS

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- Human Machine Interface

- Voltage

- 220-415 Volt (v)

Vial Filling and Cap Sealing Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- India

- Supply Ability

- 10 Pieces Per Week

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Packing only

- Main Domestic Market

- All India

- Certifications

- ISO and CE Certified

About Vial Filling and Cap Sealing Machine

Process Operation

The incoming dry vials (sterilized and siliconised) are fed through the in-feed turn table and suitably guided on the moving delrin slat conveyor belt at the required speed of the correct placement below filling unit

Automatic Vial Flling Rubber Stoppering and Cap Sealing Machine is a compact model use for filling, rubber stoppering and cap sealing of injectable liquid vials. This compact machine is also called combi vial filling stoppering and sealing machine as all three process take place on single platform. Machine is ideal choice for small but online tunnel based filling line operations.

Advanced Features for Maximum Efficiency

With an automatic grade and a robust stainless steel construction, this machine delivers consistent performance in vial filling and cap sealing. The Human Machine Interface simplifies monitoring and operational control, while its electric power supply ensures steady functionality for industrial needs.

Streamlined Pharmaceutical Packaging

Designed for efficiency, this machine optimizes the pharmaceutical packaging process by filling and sealing up to 30 vials per minute. Its versatility supports both large-scale manufacturing and smaller batch production, promoting productivity while minimizing downtime.

FAQs of Vial Filling and Cap Sealing Machine:

Q: How does the Vial Filling and Cap Sealing Machine operate in an industrial setup?

A: The machine functions automatically, utilizing electric power supply and a Human Machine Interface control system. Operators can easily set parameters for vial filling and cap sealing, ensuring minimal manual intervention and consistent output quality.Q: What materials is the machine made of, and why is it suitable for pharmaceutical environments?

A: Made from high-grade stainless steel (SS), the machine offers durability and resistance to corrosion, which is essential for maintaining hygiene and cleanliness in pharmaceutical production.Q: When is maintenance required for optimal performance of the machine?

A: Routine maintenance is recommended every few months or according to the manufacturers guidelines. This helps sustain performance, extend the equipments lifespan, and comply with safety standards.Q: Where can this Vial Filling and Cap Sealing Machine be sourced in India?

A: It is available through authorized distributors, manufacturers, suppliers, and exporters across India who specialize in pharmaceutical packaging machinery.Q: What benefits does the automatic control mode provide?

A: Automatic control ensures precise vial filling and sealing, reduces labor costs, and minimizes human error. The integrated Human Machine Interface also allows for easy adjustments and monitoring.Q: How can the capacity be adjusted to meet different production requirements?

A: Operators can configure machine settings using the control panel to process between 20 and 30 vials per minute, catering to varying production volumes.Q: What warranty and quality assurance comes with the machine?

A: The equipment is backed by a one-year warranty and offers good quality as a standard feature, providing customers with assurance and support.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Automatic Packaging Machine Category

Online Bottle Neck Trimming Machine

Minimum Order Quantity : 1 Piece

Color : Other

Automatic Grade : Automatic

Voltage : As per the client required Watt (w)

Warranty : 1 year

Drive Type : Electric

Automatic Cartooning Machine

Minimum Order Quantity : 1 Piece

Color : Silver

Automatic Grade : Automatic

Voltage : 220415 Volt (v)

Warranty : 1 Year

Drive Type : Electric

Automatic Bottle Unscramble For Plastic Bottle

Minimum Order Quantity : 1 Piece

Color : Other

Automatic Grade : Automatic

Voltage : As per the client required Volt (v)

Warranty : 1 year

Drive Type : Electric

Rotary Capless Conduction Sealer

Minimum Order Quantity : 1 Piece

Color : Other

Automatic Grade : Automatic

Voltage : As per the client required Watt (w)

Warranty : 1 year

Drive Type : Electric

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free