Ribbon Blender Machine

Price 250000 INR/ Piece

MOQ : 1 Piece

Ribbon Blender Machine Specification

- Type

- Ribbon Blender Machine

- Material

- MS

- Computerized

- No

- Automatic Grade

- Automatic

- Size

- Stnadard

- Color

- Silver

- Warranty

- 1 Year

Ribbon Blender Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 500 Pieces Per Month

- Delivery Time

- 10-15 Days

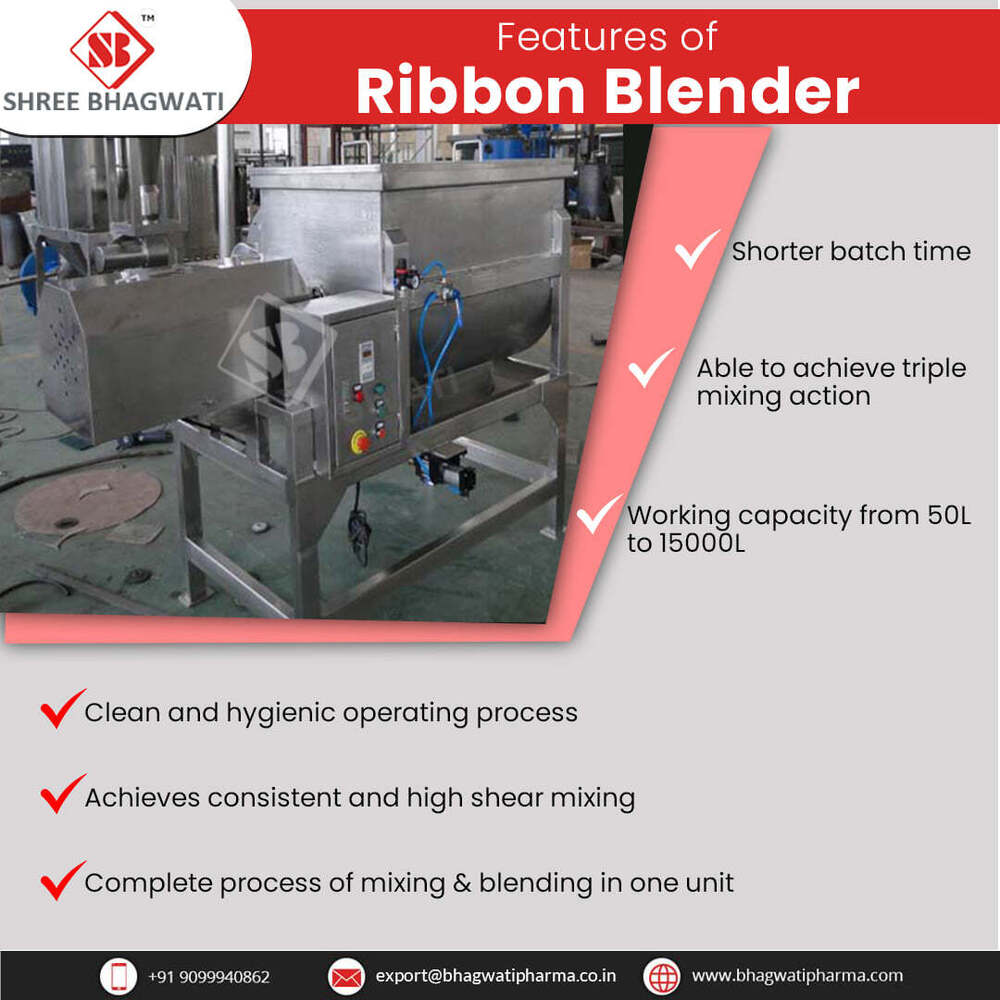

About Ribbon Blender Machine

Ribbon Blender comprises of a U-shaped horizontal trough and a specially designed Double Helical Ribbon Agitator rotating within. Ribbon Blenders are based on a proven agitator construction that provides a triple mixing action ensuring fast, efficient blending. The dimensions and configuration of the ribbons are carefully balanced to provide a movement of material within the container that avoids dead spots and gives rapid product discharge.

An alternate design is the paddle agitator. The paddles are positioned to move the material in opposing lateral directions as well as radially. The paddle design is generally employed where friable materials are being blended, and when batches as small as 15% of the total capacity are going to be mixed in the blender.

Design Highlights

An alternate design is the paddle agitator. The paddles are positioned to move the material in opposing lateral directions as well as radially. The paddle design is generally employed where friable materials are being blended, and when batches as small as 15% of the total capacity are going to be mixed in the blender.

Design Highlights

- The outer ribbon displaces the material from the ends to the center while the inner ribbon moves the material from the center to the ends. This counter-current action results in homogenous blending.

- The ribbons rotate at approximately 70 - 100 meters per minute and move the material both radially and laterally to ensure thorough blends in short cycle times.

- As the agitator rotates, the material is tumbled and carried radially around the inside of the blender.

- The pitch of the outer ribbon moves the material toward the discharge opening.

- The inner ribbon which has an opposing pitch moves the material away from the discharge opening

Efficient Mixing for Industrial Applications

A Ribbon Blender Machine achieves uniform mixing of dry powders and granules. The unique ribbon design agitates material thoroughly, reducing time and energy consumption, while maintaining product integrity. This makes it ideal for industries that demand consistent blending results.

Sturdy Construction and Longevity

With a robust mild steel body and an attractive silver finish, the machine is engineered to withstand demanding environments. The 1-year warranty further adds reassurance for those seeking a long-term mixing solution.

FAQs of Ribbon Blender Machine:

Q: How does the Ribbon Blender Machine operate?

A: This automatic-grade ribbon blender functions by rotating inner ribbons that mix powders and granules efficiently, delivering a homogeneous blend without requiring computerized controls.Q: What materials can be processed with this Ribbon Blender Machine?

A: The machine is suitable for mixing dry powders, granules, and certain paste-like materials commonly found in food, chemical, and pharmaceutical industries.Q: When is this machine recommended for industrial use?

A: The Ribbon Blender Machine is ideal when consistent, rapid blending of large batches is required, especially in manufacturing or processing environments needing automation and reliability.Q: Where is the machine available for purchase or distribution?

A: This Ribbon Blender Machine is distributed, exported, manufactured, and supplied throughout India, ensuring broad availability for local and national businesses.Q: What is the process for installation and setup?

A: Upon delivery, the machine can be installed by technical staff following the included manual. Standard-sized and easy-to-integrate, it fits seamlessly into most industrial setups.Q: How can this machine enhance production efficiency?

A: By automating the blending process, the Ribbon Blender Machine significantly shortens mixing times, improves batch consistency, and lowers operational labor costs.Q: What warranty and support benefits are offered?

A: Customers are provided with a 1-year warranty covering manufacturing defects. Support for installation, operation, and maintenance is available through the supplier or manufacturer.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Ribbon Blender Machine Category

Ribbon Blender Machine for Spices powder mixing - 30 Kgs

Minimum Order Quantity : 1 Piece

Computerized : No

Material : SS

Type : Pharmaceutical Packaging Machine

Surface Finish : Smooth

Chemical Powder Blender

Minimum Order Quantity : 1 Piece

Computerized : Yes

Material : SS

Type : Other

Surface Finish : Smooth

12000 Ltr Ribbon Blender

Price 4500000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Material : SS

Type : Industrial Ribbon Blender

Surface Finish : Smooth

Let's talk business

Please take a moment to complete this form and a business representative will get back to you swiftly

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free