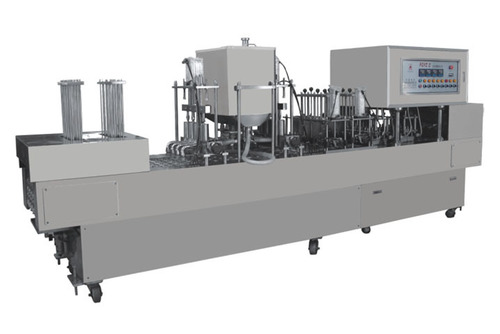

Linear Bottle Washing Machine - 150

Price 1700000 INR/ Number

Linear Bottle Washing Machine - 150 Specification

- Features

- Good Quality

- Usage

- Industrial

- Material

- SS

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- Human Machine Interface

- Drive Type

- Electric

- Voltage

- 220-415 Volt (v)

- Color

- Silver

- Warranty

- 1 Year

Linear Bottle Washing Machine - 150 Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 100 Per Month

- Delivery Time

- 7 Days

About Linear Bottle Washing Machine - 150

Automatic Linear Tunnel Type Bottle Washing Machine

Special Pocket system ensures easy and trouble free washing of Bottles from outer and inner side.

Indexing motion makes easier for syringes to move inside Bottle, when it is in stationery motion.

No Change parts are required from 2 ml to 100 ml Bottle. (Change parts are required 2 ml & 50,100 ml Bottles)

Washing cycles can be adjusted as per customer requirement.

User friendly machine, even semi skilled operator can operate the machine very easily.

A Special clutch device is incorporated for Stoppage of Machine in the event; Bottle` is over turned or over diameter.

Low RPM but High out/put.

Imported Gear Motor for +Main drive and conveyor.

A.C. Frequency drives for Main drive and conveyor.

Pumps with tank (60 litres each) 3 nos.

In feed conveyor belt system.

Suitable for 2 ml to 100 ml (. (Change parts are required 2 ml & 50,100 ml Bottle`s)

Efficient Industrial Bottle Washing

The Linear Bottle Washing Machine - 150 is engineered to handle large quantities of bottles, making it ideal for industrial operations. Its automatic system and stainless-steel construction guarantee robust performance and cleanliness, maximizing hygiene standards for bottling facilities.

User-Friendly HMI Control System

The integrated Human Machine Interface (HMI) offers intuitive operation, allowing operators to adjust settings and monitor processes efficiently. This control system enhances usability and reduces the potential for errors, ensuring a smoother workflow.

Reliable and Durable Manufacturing

Built with premium SS material and designed for longevity, this machine has a proven track record of reliability. The product is supported by distributors, exporters, manufacturers, and suppliers across India, and is backed by a one-year warranty for added assurance.

FAQs of Linear Bottle Washing Machine - 150:

Q: How does the Linear Bottle Washing Machine - 150 operate?

A: The machine uses an electric drive and functions automatically. Operators control and monitor the washing process via an intuitive Human Machine Interface, which streamlines workflow and simplifies adjustments.Q: What industries commonly use the Linear Bottle Washing Machine - 150?

A: It is primarily intended for industrial use in sectors such as beverage, pharmaceutical, and food processing, where high-standard bottle cleaning is crucial for product quality and hygiene.Q: When should the Linear Bottle Washing Machine - 150 be used?

A: It should be employed when consistent, large-scale bottle cleaning is required. Its automatic grade and robust design make it suitable for regular operation in demanding production environments.Q: Where is the Linear Bottle Washing Machine - 150 available for purchase?

A: The machine is distributed, exported, manufactured, and supplied throughout India, making it accessible to businesses across the country seeking efficient bottle cleaning solutions.Q: What is the process involved in using the bottle washing machine?

A: Simply load the bottles, set the required parameters using the HMI, and the machine will automatically conduct the washing cycle, ensuring each bottle is cleaned efficiently and thoroughly.Q: What are the main benefits of using this linear bottle washing machine?

A: The key advantages include improved hygiene, increased efficiency, durability due to stainless steel construction, easy operation via HMI, and the reassurance of a one-year warranty.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Automatic Packaging Machine Category

Carton Check Weigher

Price 850000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 year

Drive Type : Electric

Automatic Grade : Automatic

Material : Stainless steel

6000 BPH 500 ML Automatic Pure Water Production Line With Reverse Osmosis System

Minimum Order Quantity : 1 Piece

Warranty : 1 year

Drive Type : Electric

Automatic Grade : Automatic

Material : Stainless steel

Fully Automatic Shrink Sleeve Label Applicator Machine

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Drive Type : Electric

Automatic Grade : Automatic

Material : SS

Linear Type Yougourt Cup Filling And Sealing Machine

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Drive Type : Electric

Automatic Grade : Automatic

Material : SS

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free