High Speed Homogenizer

MOQ : 1 Piece

High Speed Homogenizer Specification

- Type

- Pharmaceutical Packaging Machine

- Material

- Stainless steel

- Capacity

- As per the Client required Kg/hr

- Computerized

- Yes

- Control Mode

- Automatic

- Voltage

- As per the client required Watt (w)

- Power

- As per the client required Watt (w)

- Weight (kg)

- In kgs Kilograms (kg)

- Dimension (L*W*H)

- In inches Inch (in)

- Color

- stainless steel

- Warranty

- 1 year

High Speed Homogenizer Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- India

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Days after Acceptance (DA), Cash in Advance (CID), Cheque

- Supply Ability

- 30 Pieces Per Week

- Delivery Time

- 81-0 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Packing Only

- Main Domestic Market

- All India

- Certifications

- ISO and CE Certified

About High Speed Homogenizer

Working Principle:-High speed mechanical and hydraulic shear forces are the real key to the success of this machine. Rotor & stator generates as hearing action which insures that materials being processed are subjected to thousands of shearing actions each minute.

Stages:-

High speed rotor operating at close clearance to stator draws material in from the bottom of the mixing vessel and subjects it to intense mixing and shearing action.

The rotor accelerates the product towards the blades periphery. There it is expelled through the stator openings into the body of the mix while undergoing an intensive mechanical and hydraulic shearing action. Simultaneously new material is drawn in.

The expelled mixture is deflected by the tank wall completing the circulation pattern.

Special Features of Vats & Vessels Homogenizer:-

- Active ingredient in the range of0.5% can be mixed

- M.O.C. - SS 304, SS 316, SS 316L

- Low Maintenance, easy cleaning.

Customizable Performance for Pharmaceutical Needs

This homogenizer stands out with its fully customizable specifications, including power, voltage, capacity, and dimensions, tailored to meet your application requirements. Engineered from premium stainless steel, the machine guarantees durability and hygiene, essential in pharmaceutical packaging. Its computerized and automatic control mode contributes to consistent results during rigorous processing tasks.

Seamless Operation Across Indian Markets

As a distributor, manufacturer, and supplier situated in India, we cater to a diverse customer base with well-supported logistics and service networks. Our export capabilities ensure that the high speed homogenizer reaches domestic and international clients efficiently, promoting revolutionary packaging technology throughout the industry.

FAQs of High Speed Homogenizer:

Q: How is the power and voltage of the High Speed Homogenizer determined?

A: The power and voltage specifications of the homogenizer are customized based on individual client requirements, ensuring optimal performance for specific applications and facility standards.Q: What materials are used in manufacturing the High Speed Homogenizer?

A: The homogenizer is manufactured from high-quality stainless steel, offering superior durability, corrosion resistance, and compliance with pharmaceutical hygiene standards.Q: When should I use a high speed homogenizer in my pharmaceutical process?

A: A high speed homogenizer is ideal when efficient mixing, emulsification, and particle reduction are required during pharmaceutical packaging or formulation stages.Q: Where can I purchase or inquire about this homogenizer in India?

A: You can obtain this machine through our network of distributors, suppliers, exporters, or directly from the manufacturer, all located throughout India for accessible service.Q: What is the process for customizing the dimensions and capacity of the equipment?

A: Clients can specify their desired dimensions in inches and required processing capacity in kg/hr, allowing the manufacturer to tailor the machine to meet unique operational needs.Q: How does the computerized automatic control mode benefit users?

A: The automated and computerized control system streamlines operations, enhances accuracy, and minimizes manual intervention, resulting in faster, reliable, and consistent production.Q: What warranty coverage comes with the High Speed Homogenizer?

A: Each homogenizer is backed by a 1-year warranty, providing quality assurance and access to support for maintenance or potential repairs during the coverage period.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Dry & Wet Granulation Machine Category

Inline Homogenizer

Price 200000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Voltage : 220 Volt (v)

Material : Stainless Steel

Warranty : 1 Year

FBG - Fluid-bed Granulator

Minimum Order Quantity : 1 Piece

Computerized : Yes

Voltage : As per the client required Volt (v)

Material : Stainless steel

Warranty : 1 year

Mass Mixer

Price 250000 INR / Unit

Minimum Order Quantity : 1 Piece

Computerized : Yes

Voltage : as per customer requirement Watt (w)

Material : stainless steal

Warranty : 1 year warranty

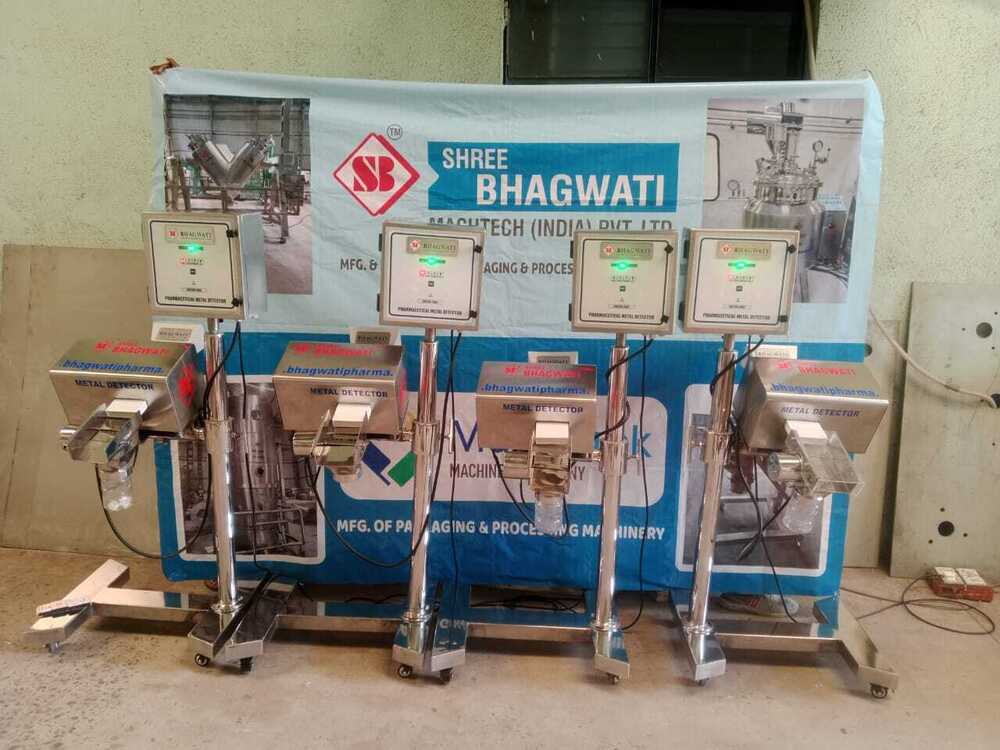

Tablet Metal Detector

Price 350000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Voltage : 110215 Volt (v)

Material : SS

Warranty : 1 year

Let's talk business

Please take a moment to complete this form and a business representative will get back to you swiftly

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS