Cone Mill

Price 550000 INR/ Unit

Cone Mill Specification

- Usage & Applications

- Industrial

- Features

- Good Quality

- Type

- Cone Mill

- Material

- SS

- Computerized

- No

- Control Mode

- Automatic

- Voltage

- 220-415 Volt (v)

- Color

- Silver

- Warranty

- 1 year

Cone Mill Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 50 Units Per Month

- Delivery Time

- 10-15 Days

About Cone Mill

Conical mills, also known as cone mills or conical screen mills, are essential equipment in the field of size reduction and material management processes. These machines play an important role in industries requiring precision particle size reduction with tighter particle size distribution.

A conical mill is a specialized machine designed for the precise size reduction of various materials. It involves a rotor known as an impeller that rotates inside a conical screen. The material is fed into the cone mill machine, where it is reduced to the desired particle size primarily through impact, attrition, compression, and shearing.

Precision Milling with Automatic Control

This Cone Mill enables automatic and consistent particle size reduction, making it an essential tool for pharmaceutical, chemical, and food processing sectors. With no computerized components, operators have direct control, ensuring stable performance even in demanding environments.

High-Quality Stainless Steel Construction

Crafted from premium-grade stainless steel, the Cone Mill resists corrosion and supports rigorous industrial use. Its silver finish adds an aesthetic touch while maintaining robust operational reliability, ensuring longevity and safety for your facility.

FAQs of Cone Mill:

Q: How does the Cone Mill operate under different voltage ranges?

A: The Cone Mill functions efficiently between 220 and 415 Volts, making it adaptable for varied industrial power supplies. Automatic control mode ensures seamless operation, regardless of voltage fluctuations within this range.Q: What are the main benefits of using a Cone Mill in industrial applications?

A: This Cone Mill offers consistent particle size reduction, enhanced product quality, and reliable performance. Its good-quality construction and automatic operation improve productivity and minimize downtime in industrial processes.Q: Where can I use the Cone Mill, and who supplies it?

A: The Cone Mill is supplied, exported, and manufactured in India. It is suitable for pharmaceutical, food, and chemical industries, and available from authorized distributors and suppliers across India.Q: What is the typical process for using the Cone Mill?

A: To use the Cone Mill, operators feed material into the machine, where it is milled automatically to the desired particle size. The process does not require computerized controls and is straightforward for skilled technicians.Q: When can I expect the warranty coverage for my Cone Mill?

A: The Cone Mill comes with a standard 1-year warranty from the date of purchase, covering manufacturing defects and performance issues encountered under normal industrial use.Q: Why is stainless steel (SS) material preferred in the Cone Mill?

A: Stainless steel offers excellent durability, corrosion resistance, and hygienic properties, making it ideal for demanding industrial environments and applications that involve sensitive materials.Q: How will the automatic control mode benefit my production process?

A: Automatic control reduces manual intervention, leading to uniform product quality and operational efficiency. It simplifies milling procedures and helps maintain a steady workflow in your facility.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dry & Wet Granulation Machine Category

High Efficiency Coating Machine

Price 2500000 INR / Unit

Minimum Order Quantity : 1 Piece

Warranty : 1 year

Control Mode : Automatic

Material : Stainless steel

Computerized : Yes

Conventional Coating Pan

Minimum Order Quantity : 1 Piece

Warranty : We provide warranty of 12 months from the date of dispatch against manufacturing defects Or default workmanship. Warranty does not cover any electric or electronic parts such as AC variable drive, motor, PLC, sensor, relay etc.

Control Mode : Automatic

Material : stainless steal

Computerized : Yes

Mass Mixer

Price 250000 INR / Unit

Minimum Order Quantity : 1 Piece

Warranty : 1 year warranty

Control Mode : Automatic

Material : stainless steal

Computerized : Yes

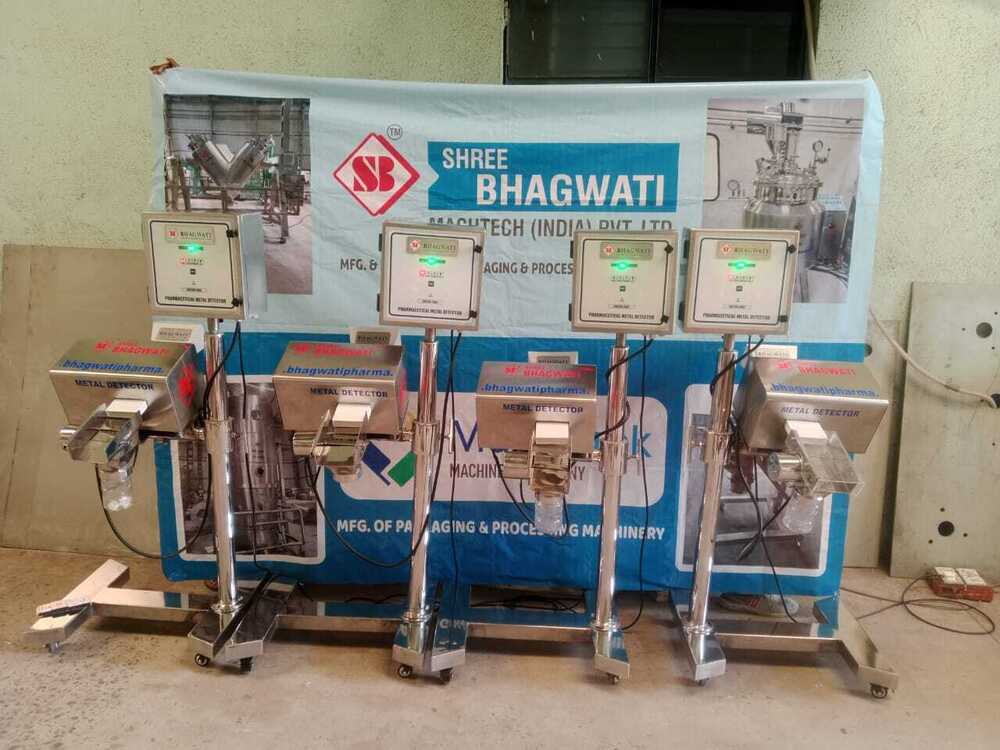

Tablet Metal Detector

Price 350000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 year

Control Mode : SemiAutomatic

Material : SS

Computerized : No

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS