Automatic Pressure Filling Machine

Automatic Pressure Filling Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Telegraphic Transfer (T/T), Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 30 Pieces Per Month

- Delivery Time

- 8 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Packing Only

- Main Export Market(s)

- Australia, North America, Eastern Europe, Africa, Western Europe, Central America, Middle East, South America, Asia

- Main Domestic Market

- All India

- Certifications

- CE & ISO Certified

About Automatic Pressure Filling Machine

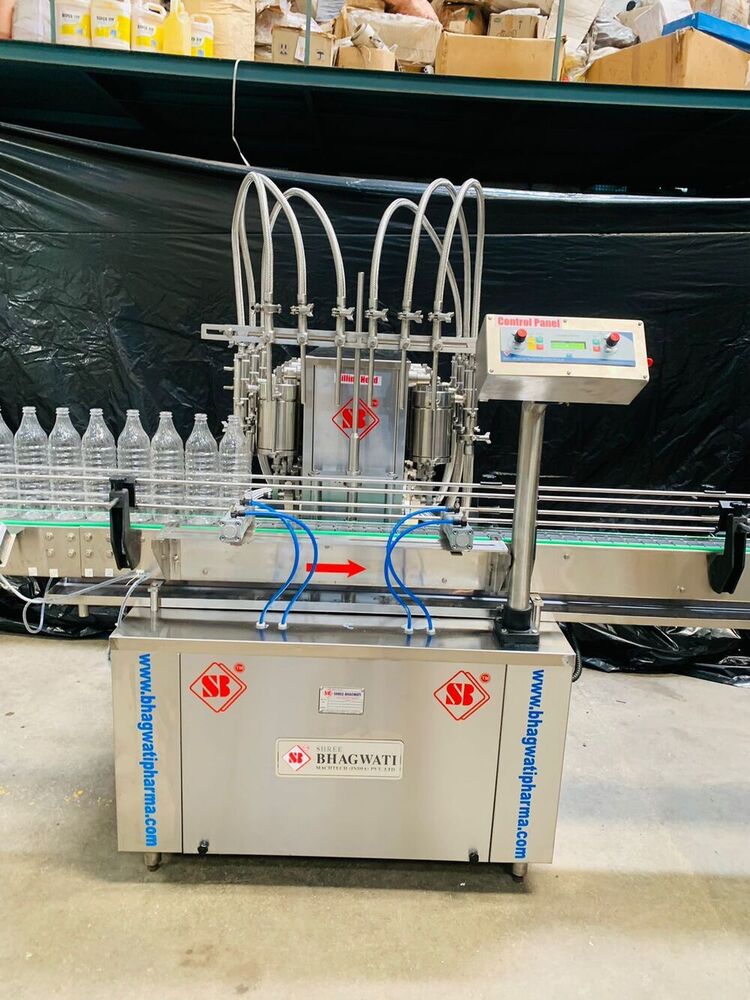

Automatic Pressure Filling Machine

(Photograph is for the reference purpose only. Machine Construction & Specification are subject to change without prior Notice due to Continues up-gradation Process)

Introduction

In pressure overflow filling systems the product is pumped or gravity fed from a tank through a filling valve to the container. The filling valve contains an over flow tube to drain the excess product back to the supply tank and prevent overfill. The fill level of the container is determined by the depth of the overflow port within the neck of the container. When the product reaches the overflow port, the fill is completed, but the flow continues through the overflow tube until the seal on the container is broken and the valve sleeve covers the ports in the filling nozzle and stops the flow. The fill level will be the same regardless of bottle inconsistencies.

Key Feature :

- No Bottle No Filling System

- Pneumatic Diving nozzle

- Pneumatic Bottle Stoppering Arrangement

- Pneumatic operated valve

- Stainless Steel no drip Fill Heads

- On the fly adjustments

- Stainless Steel drip collection tray

- Stainless Steel Food Grade Manifold with Tri-clover connections

- 304/316 Stainless Steel Food Grade Over flow Tank and float tank

- HDPE reinforced tubing

- 10 Feet Stainless Steel variable speed Conveyor

- Suitable Transfer Pump

| Brand | Bhagwati |

| Model | SBFILL |

| Fill Volume | 200 ML to 5 Ltrs |

| Viscosity Range | 2000 CPS ( Centipoises) |

| Foamy Product*** | Yes |

| Corrosive Product**** | Yes |

| Heated Product***** | Yes |

| Electrical Specification | 415v , Single Phase, 50 Hz |

| Air Requirement | 80 to 100 PSI @ 2 CFM |

| Overall Dimension | 1981.2 mm (H) X 1422.4 mm(D) X 3048mm(L) (Approx.) |

| Weight (Approx.) | 1100lbs. (498.95 Kg.) |

High-Precision Filling for Diverse Liquids

Engineered to handle a wide range of liquid products, this filling machine provides dynamic performance with volumes from 200 ml up to 5000 ml. Its automatic, PLC-guided operation ensures every container is filled accurately and efficiently, reducing waste and promoting high throughput. Stainless steel construction safeguards against corrosion and extends operational lifespan.

User-Centric Automation and Customization

Featuring a computerized interface and PLC control, the machine streamlines usage and allows operators to adjust configurations easily. Voltage can be tailored as per customer requirements, ensuring compatibility with varied power setups. Its automated, electric-driven system boosts productivity while minimizing human intervention in the filling process.

Assured Quality and Support

Supplied by leading distributors, exporters, manufacturers, and suppliers in India, this pressure filling machine is supported by a one-year warranty. Comprehensive after-sales service ensures you get the assistance you need, maximizing uptime and maintaining seamless operations in your bottling line.

FAQs of Automatic Pressure Filling Machine:

Q: How does the Automatic Pressure Filling Machine operate?

A: The machine utilizes a fully automatic, computerized PLC control system paired with an electric drive to fill containers with liquid efficiently. Operators can easily set fill volumes and monitor the process through a user-friendly interface, ensuring precise and consistent results.Q: What types of materials and capacities can the machine handle?

A: Crafted from durable stainless steel, the machine is suitable for a wide array of liquid products. It accommodates filling volumes from 200 ml to 5000 ml, providing flexibility for different packaging sizes.Q: When is routine maintenance required for this filling machine?

A: Routine maintenance is recommended at periodic intervals as outlined in the manufacturers guidetypically quarterly or as needed based on usage. The stainless steel build simplifies cleaning, and support is available during the one-year warranty period for any technical concerns.Q: Where can I source or purchase this machine in India?

A: The Automatic Pressure Filling Machine can be obtained from reputable distributors, exporters, manufacturers, and suppliers located throughout India. Consult authorized sellers to ensure product authenticity and warranty coverage.Q: What is the usage process for this PLC-controlled filling machine?

A: To operate, simply set the desired parametersfill volume, speed, and voltagethrough the touchscreen interface. Initiate the automatic cycle, and the machine will accurately fill each container without manual intervention, aided by the precise PLC system.Q: What are the key benefits of using this automatic filling machine?

A: This machine offers enhanced productivity, uniform filling accuracy, and lower manual labor requirements. Its stainless steel body ensures durability, while the PLC and computerized controls guarantee reliability, cost-effectiveness, and easy integration into various production lines.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Liquid Filling Machine Category

Automatic Win-e Filling Machine

Price 1500000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : Human Machine Interface

Automatic Grade : Automatic

Computerized : No

Drive Type : Electric

6 Head Volumetric Essential Oil Filling Machine

Price 675000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : Human Machine Interface

Automatic Grade : Automatic

Computerized : No

Drive Type : Electric

Semi Twin Head Liquid Filling Machine

Price 150000 INR / Unit

Minimum Order Quantity : 1 Piece

Control System : Frequency Speed Control

Automatic Grade : Automatic

Computerized : No

Drive Type : Electric

Liquid Syrup Filling Machine

Price 300000 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Human Machine Interface

Automatic Grade : SemiAutomatic

Computerized : No

Drive Type : Electric

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free