Automatic Induction Cap Sealer

Price 450000 INR/ Unit

MOQ : 1 Unit

Automatic Induction Cap Sealer Specification

- Features

- Good Quality

- Usage

- Industrial

- Material

- SS

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- Human Machine Interface

- Drive Type

- Electric

- Warranty

- 1 Year

Automatic Induction Cap Sealer Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 7 Days

About Automatic Induction Cap Sealer

Induction Cap Sealer with Slat conveyor, Induction Cap Sealing Machine suitable for the bottle, Jar, Jerry Can, Oil, Pharma, Food and Cosmetic Bottle.

Technical Details: :

- The Wad basically consists of four layers:

- Cardboard or Foam Packing.

- Wax Layer.

- Aluminium Foil.

- Sealing Film.We see a pulp board packing material as the retaining wad, the wax dot pattern layer, the aluminium foil and the sealing film. The lines of force radiate through the foil and induce current flow in it. This increases the temperature of the foil. Due to this, the sealing film melts and adheres to the lip of the container. After the seal is broken, the board or foam packing is retained by the cap.

Robust and Efficient Sealing

Experience consistent cap sealing with our semi-automatic induction cap sealer. Its electric drive and stainless steel build promote longevity and low maintenance, meeting industrial standards. Ideal for manufacturers seeking reliable packaging solutions.

Advanced Control System

Featuring a Human Machine Interface, this sealer allows easy monitoring and management of the sealing process, enhancing accuracy while minimizing operational complexity. Users can maintain optimal settings according to their production requirements.

FAQs of Automatic Induction Cap Sealer:

Q: How does the Automatic Induction Cap Sealer improve industrial packaging efficiency?

A: This cap sealer automates the process of sealing containers, minimizing manual involvement and reducing errors. The electric drive and semi-automatic operation allow for faster throughput, making packaging lines more productive.Q: What materials can be sealed using the induction cap sealer, and what is its build quality?

A: The machine is crafted from stainless steel and designed to work with various container types that support induction sealing, ensuring both durability and compatibility with diverse packaging requirements.Q: When should I consider using a semi-automatic induction cap sealer in my operations?

A: If your business requires efficient, reliable, and tamper-evident sealing for medium-to-high volume packaging with user-friendly operation, this sealer is an excellent choice due to its automated features and ease of use.Q: Where is this induction cap sealer available for purchase and support?

A: We supply, distribute, and export the Automatic Induction Cap Sealer throughout India. Our manufacturing and support units provide warranty service and technical assistance locally.Q: What is the process of operating the induction cap sealer with the Human Machine Interface?

A: Users interact with the Human Machine Interface to set parameters for the sealing process. The machine automates the application of induction heat, securing the cap to the container with minimal operator intervention.Q: Is computerized operation required for this cap sealer, and what are the benefits of its current system?

A: No computerized operation is needed. The Human Machine Interface offers sufficient control for semi-automated workflows, simplifying operation while maintaining high quality and consistency in sealing.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Automatic Packaging Machine Category

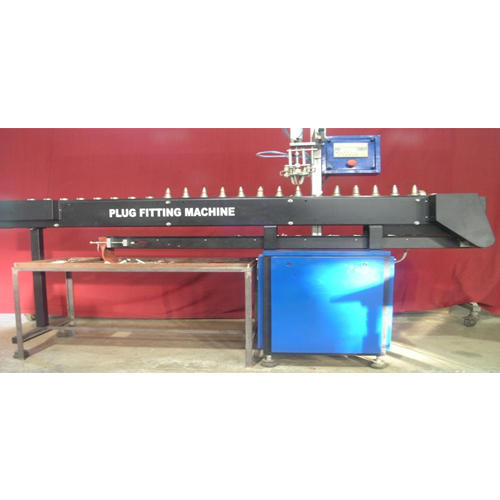

Plug Fitting Machine

Minimum Order Quantity : 1 Piece

Material : Stainless steel

Color : Other

Warranty : 1 year

Computerized : Yes

5 Gallon Water Barrel Washing Filling Capping Machine

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Color : Other

Warranty : 1 Year

Computerized : Yes

Capsule Inspection Polishing Machine

Minimum Order Quantity : 1 Piece

Material : Stainless steel

Color : stainless steel

Warranty : 1 year

Computerized : Yes

Automatic Single Nozzle Pickle Filling Machine

Price 600000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : SS

Color : Silver

Warranty : 1 Year

Computerized : No

Let's talk business

Please take a moment to complete this form and a business representative will get back to you swiftly

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free