Showroom

Rotocone vacuum dryers

and tray dryers are used

for drying and processing various materials in industries such as

pharmaceuticals, chemicals, and food. They offer benefits such as low energy

consumption, efficient drying, gentle handling of sensitive materials, and

customizable features such as temperature, pressure, and agitation control.

Liquid oral manufacturing

plants are designed

for the efficient and sterile production of liquid medications. They typically

feature automated processes for mixing, filtration, sterilization, and filling,

as well as options for quality control and documentation. These plants can

improve production speed, accuracy, and regulatory compliance while reducing

manual labor and contamination risks.

Dry and wet granulation machines are used in the pharmaceutical, food, and chemical industries to convert powders into granules for easier handling, transportation, and storage. They can improve flow properties, reduce dust, and enhance product performance. Some machines may also include options for mixing, drying, and coating granules.

Our dry and wet tablet

granulation line is designed for efficient and precise granulation of

medications. It features a modular design for easy customization and scale-up,

high-speed processing, and minimal waste. Our granulation line ensures

consistent product quality, regulatory compliance, and increased production

efficiency, reducing overall costs.

ROPP and screw capping

machines are used for

sealing glass containers of liquid medications with metal caps. They offer

high-speed and accurate capping, reducing human error and increasing production

efficiency. These machines can handle various container sizes and cap types.

They ensure product safety, and integrity.

Sticker labelling

machines are designed

for accurate and high-speed labelling of glass containers of liquid

medications. They can handle various container sizes and shapes. These machines

feature a user-friendly interface, precision labeling, and low maintenance

requirements. They ensure consistent and compliant labeling, increasing

efficiency and product quality in pharmaceutical manufacturing.

Powder filling machines are designed for accurate and efficient

filling of powders into containers such as bottles, bags, or pouches. They

typically feature adjustable filling speeds and volumes, as well as options for

weighing, counting, and vibrating to ensure precise measurements.

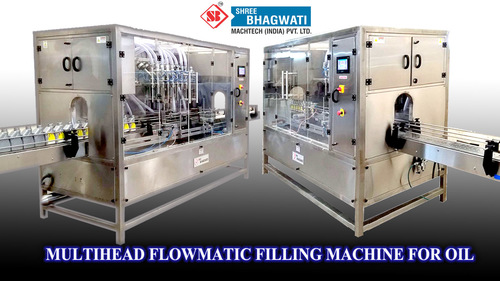

Bottle and vials liquid

filling machines offer

precise and accurate filling of liquid medications into glass containers. They

can handle a variety of liquid viscosities and container sizes. They reduce human

error, increase production speed, and ensure consistent product quality.

These are essential for efficient

pharmaceutical manufacturing.

Plastic and aluminum tube

filling machines are used

for filling and sealing tubes with various products. They typically feature

automatic filling and sealing processes, adjustable filling volumes, and

compatibility with different tube sizes and materials. Some machines may also

include options for printing, coding, and labeling tubes.

We offer Vial & Bottle

Washing Machines designed for pharmaceutical manufacturing. These machines

use a variety of cleaning methods such as spraying, soaking, and ultrasonic

waves to clean and sterilize glass containers. They are designed for high

efficiency and are compliant with regulatory guidelines.

Vial and bottle

inspection machines are

designed for quality control in pharmaceutical manufacturing. These machines

feature high-speed and precise inspection of glass containers for defects such

as cracks, chips, and contamination. They reduce human error, ensure product

safety, and compliance with regulatory guidelines.

Capsule and tablet

blister packing machines are

designed for efficient and precise packaging of medications into blister packs.

They feature high-speed packaging, accurate dosing, and customized blister designs.

These machines can handle a variety of capsule and tablet sizes, reducing human

error and increasing production efficiency.

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free