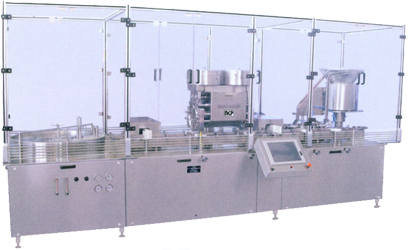

Twin Track Twelve Head Liquid Filling Machine

2.00 - 25.00 INR

Product Details:

X

Twin Track Twelve Head Liquid Filling Machine Price And Quantity

- 1 Piece

- 2.00 - 25.00 INR

Twin Track Twelve Head Liquid Filling Machine Trade Information

- Cash Against Delivery (CAD) Letter of Credit (L/C) Letter of Credit at Sight (Sight L/C) Telegraphic Transfer (T/T) Cash in Advance (CID) Cheque Cash Advance (CA)

- 30 Piece Per Month

- 8 Week

- Yes

- Contact us for information regarding our sample policy

- Wooden Packing Only

- Australia North America Eastern Europe Middle East Africa Western Europe Central America South America Asia

- All India

- CE & ISO Certified

Product Description

Twin Track Twelve Head Liquid Filling Machine For Bottles

|

||||||||||||||||||||||||||

|

||||||||||||||||||||||||||

|

||||||||||||||||||||||||||

| * Depends on size, shape and Neck Dia of container, Fill volume and nature of liquid etc. ** Can be supplied as per customer requirements. *** With help of change parts. |

||||||||||||||||||||||||||

|

||||||||||||||||||||||||||

|

||||||||||||||||||||||||||

Enter Buying Requirement Details

Other Products in 'Bottle and Vials Liquid Filling Machine' category

Let's talk business

Please take a moment to complete this form and a business representative will get back to you swiftly

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free